Optical Deformation Measurement for Verification of FE Models - Principles

The most common cause of failure in electronics is thermal fatigue. For a well-founded evaluation of the reliability of a structure, experimental tests are necessary to analyze faults and determine the physical causes of faults.

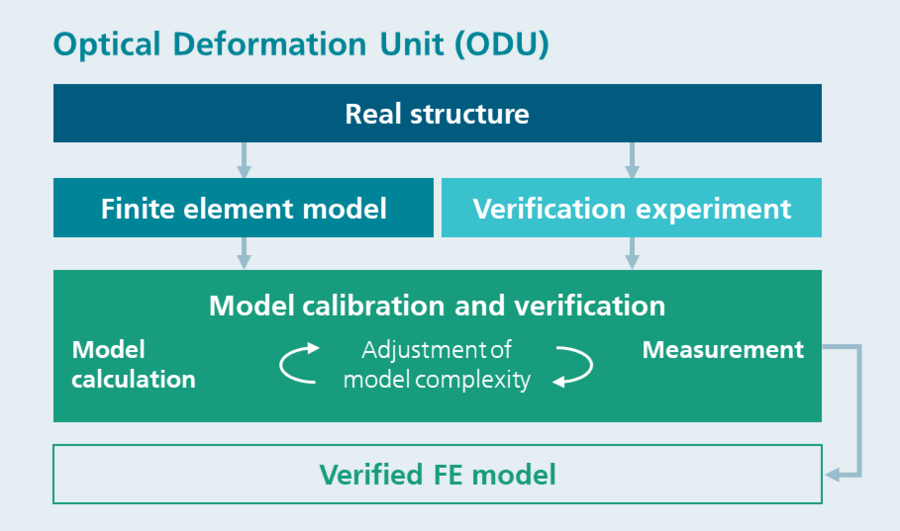

Due to increasingly shorter product development cycles and the resulting time pressure, supplementary simulations based on finite element models offer a considerable advantage for understanding structural behavior. The scope of experimental tests can thus be considerably reduced.

The virtual environment allows a reliability prediction based on the calculation results and enables the reliability assessment to be carried out in a reasonable time.

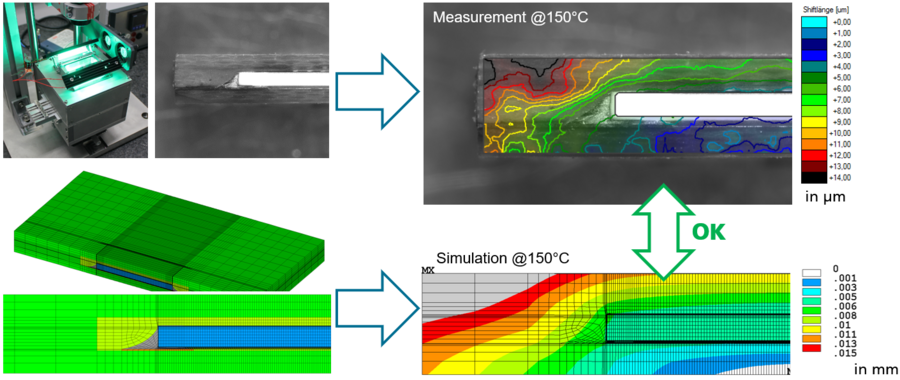

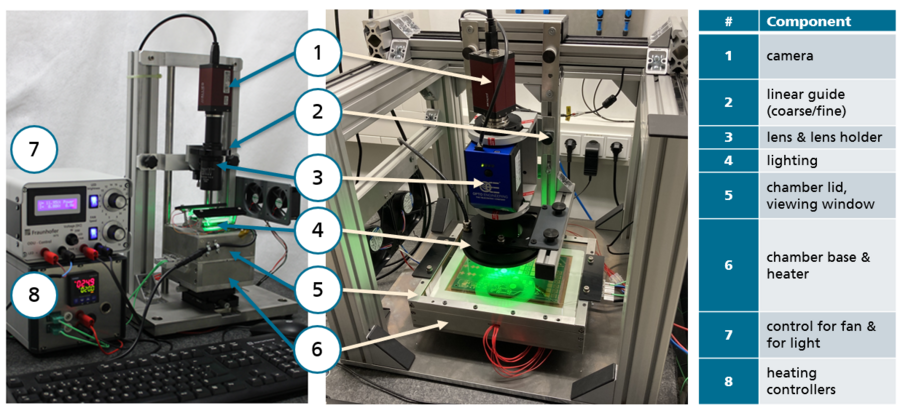

The Optical Deformation Unit (ODU) was developed at Fraunhofer IKTS to confirm the credibility of the results of the FEM calculations. This can be used to carry out deformation experiments that enable FEM model calibration and verification.

Test rigs for optical measurement (Optical Deformation Unit 1 & 2)

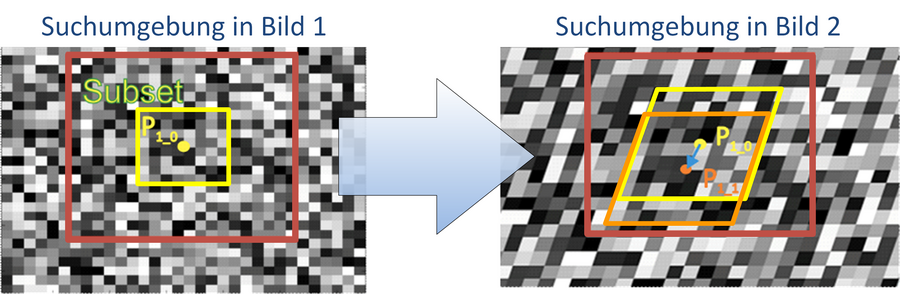

There are few measurement methods that can analyze thermomechanical deformations with high resolution. Digital image correlation makes this possible and is therefore a powerful tool in tandem with simulation. The measuring principle is based on the repetition of the following essential steps:

1. registration of features in an evaluation area of the reference state (reference image)

2. recognition of these characteristic features in the measurement state (measurement image)

3. quantification of the position of the relevant image sections in relation to each other using correlation algorithms

4. determination of the relative displacement of the corresponding points and their surroundings by deformation field visualization

Range of services

- Verification of FEM models through targeted high-resolution measurement on prepared samples

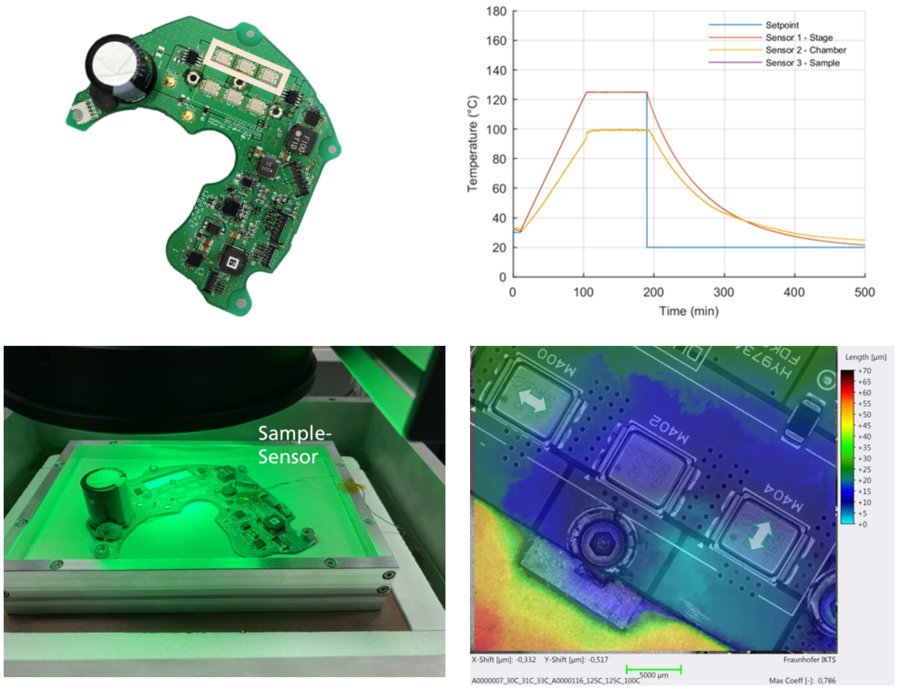

- Analysis of the global deformation of entire assembled printed circuit boards/assemblies for

- Extraction of information on thermal expansion (CTE) and transverse contraction on bulk samples

Technische Details

| # | Component | Specification |

|---|---|---|

| 1 | camera | 2/3-inch CCD sensor, (2452 x 2054) px |

| 2 | linear guide (coarse/fine) | low-friction, continuously |

| 3 | lens & lens holder | telecentric; flexible changeable |

| 4 | Beleuchtung | LEDs 525 nm |

| 5 | chamber lid, viewing window | removable lid, special glass |

| 6 | chamber base & heater | ODU-1: ceramic resistor 200W total power, heating up to 180 °C, stagesize (35 x 35) mm ODU-2: heating cartridges 800W total power, heating up to 250°C, stagesize (140 x 200) mm |

| 7 | control for fan & for light | adjustable fan speed, dimmable LEDs |

| 8 | heater control | programmable heating profiles |

Examples