Dynamic Topography Measurement - Principles

Beside the exact measurement of topography of static surfaces, in electronic packaging it is especially interesting how components, substrates or both in combination behave under changing thermal conditions. Caused by the inner structure composed of different materials with specific coefficients of thermal expansion (CTE) components and substrates change their geometrical shape e.g. during soldering. Dynamic in-situ measurement of bow and twist of such objects can generate important findings about possible failure reasons during interconnecting.

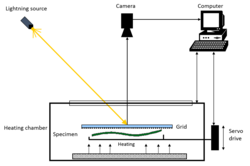

One measurement method for that is the so-called Thermoiré method. The object that shall be characterised is placed in a chamber in which a controlled temperature profile can be realised. A lightning source illuminates the object through a glass plate in the chamber’s cover plate with a grid of small lines integrated in it. The light will be reflected on the object surface and passes again the grid. A characteristic shadow image is generated depending on the current topography of the object surface. This image is captured by a camera and then re-calculated by software algorithms into a height profile of the object surface.