Acoustic Microscopy - Principles

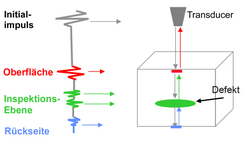

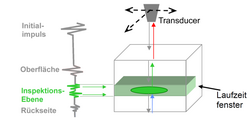

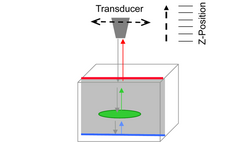

Scanning Acoustic Microscopy (SAM) uses the spreading of acoustic waves in solids to investigate specimen. Acoustic waves on one hand spread with different speed depending on the material. On the other hand, they are reflected at the interface between two materials differently. This generates an “echo” signal that is characterized by a specific change of signal amplitude and signal frequency. One can use software algorithms to calculate an image of the inner layer structure of the specimen based on the received echo signals (amplitude, frequency, time-of-flight) during a scan. Different scan modes allow different analyses of the data.

Piezo electric crystals of ceramics are often used to generate the acoustic waves. The so-called transducers are working at a fixed nominal frequency between 10 MHz to 250 MHz. The actual frequency defines the reachable penetration depth and the lateral resolution. Higher frequencies allow higher resolutions but lower penetration depths, lower frequencies vice versa. The axial resolution depends on the material and can be expected in the range of 20 µm. Intermediate layers in the specimen that are filled with a liquid or gas can already be detected at layer thicknesses of some 10 nm because of the big difference of the acoustic impedance of that layer compared to the neighbouring ones. Thereby this method is very useful to detect delamination in the layer structure.

Material containing geometrically undefined particles, e.g. filled polymers, are different to be investigated, because the echo signal is spread in many different directions. In addition, it has to be considered that all specimen must be bathed completely into a coupling fluid like de-ionised water.