Physical Surface Characterisation - Principles

The characterisation of physical properties of interfaces and surfaces in electronic packaging is important to understand different influencing factors during interconnecting. It is possible to determine those properties of the different parts before interconnecting them as well as to determine the adhesive strength of the interconnection afterwards.

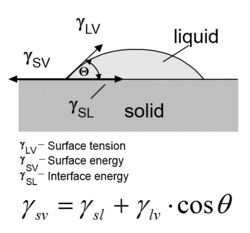

One interesting physical parameter is the surface energy of the interface. Interacting with the surface tension of a liquid applied to the surface (e.g. the melted solder during soldering) it influences the wetting behaviour and hence the forming of the interconnection. Surface energy of solids and surface tension of liquids can be measured using a so-called contact angle measurement system.

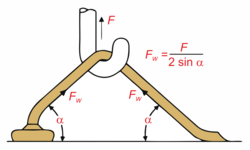

One criterion to evaluate the quality of a bonded or soldered interconnection is to measure the force that is necessary to release that interconnection by pulling or shearing. This destructive test is done using Pull Shear Testers and testing couple of interconnects. The measured forces and the failure modes are analysed.